Cantilever compact mill stands are. Two basic models the force model and the crownshape model dominate major tasks of mill design.

Mill Guides Guides Rollers Metallurgical Solutions Provider

Rolling mills having single-stand type are.

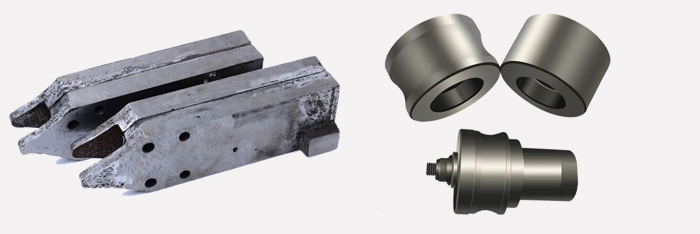

. Guide plates are installed in the roughing stands and intermedate stands. Consulting Engineersprocess control and automation direct reduction arc furnace melting oxygen steelmaking billet bloom round and slab casters rolling millscomprehensive engineering including problem solving optimization retrofits planning feasibility studies environmental services site selection market studies project and construction management. Pre-notching pre-cut lengths multiple gages.

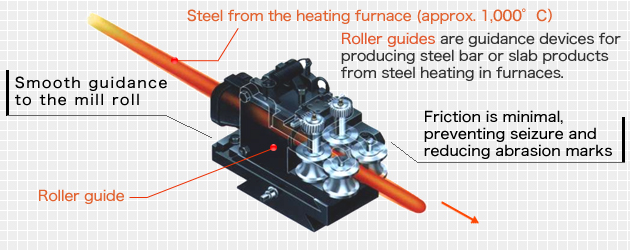

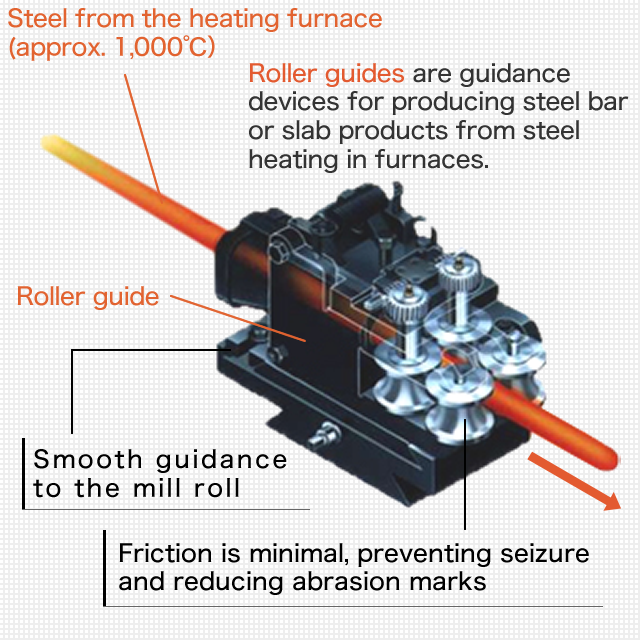

Roller guide box finds applications in continuous rolling operations in which the stock that is being rolled is properly twisted between each two adjacent rollers in rolling mills. Ad Pepetools is the only American manufacturer to produce design and build rolling mills. Rolling mill is used to reduce successively the thickness of the metal strip as per the requirement.

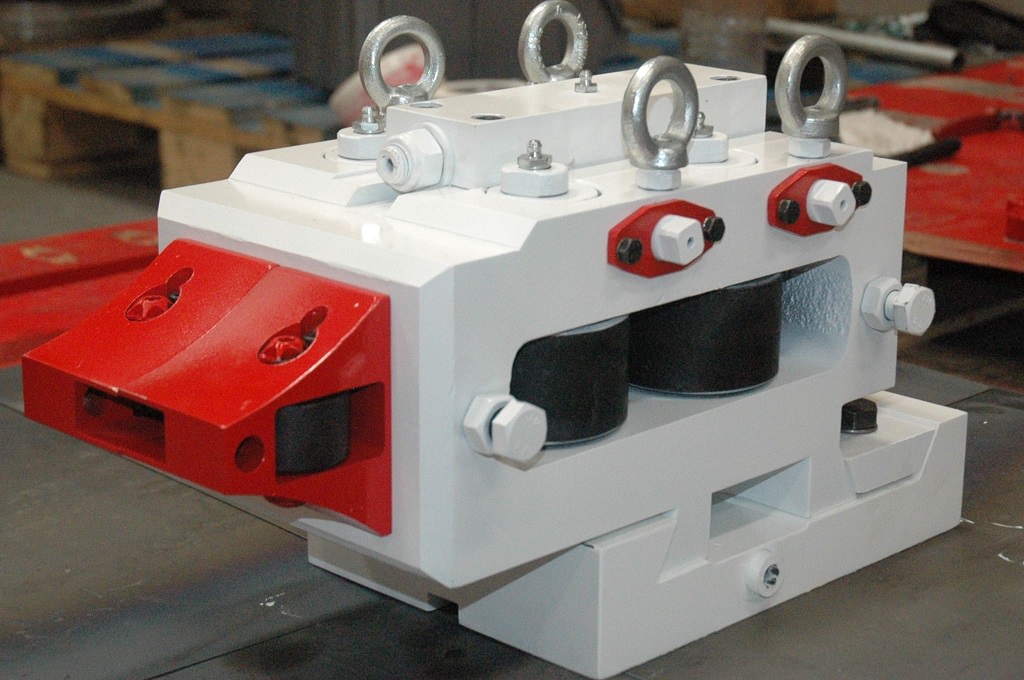

Our roller entry guide is made in sliding type plus rolling type. Since the friction on the milled steel is minimal seizure is prevented and abrasion marks are reduced making this machinery vital in improving the yield rate and quality of the product. Three high rolling mills.

This five-day instructor-led course is designed to improve mill related engineers the basic skills on rolling mill parameters calculation for mill design development and operation. Our rolling mill guides box is offered with the. Two High Rolling Mills.

100 Free to Use. It is provided with heavy taper roller bearings for different sections. Develops guide plates with the material of Z50CrMo and 2Cr13.

Features of the Rolling Mill Guides Our mill guide has excellent features such as corrosive resistance unique design and simple maintenance. In principle the billet will be rolled in the same way as in conventional rolling up to the intermediate rolling mill. Roller Guide for rolling mill are a series of rollers that determine the angle and direction of the steel as it is guided through the rolling mill to the mill roll.

Combination rolling mills come with a roller that has a flat and groovy surface. These original concepts have been continuously developing to meet the market. Height Max Min Pitch Width Fixing Method.

ROLLER GUIDE TKRE TYPE. Choose from a wide selection of high quality rolling mills. Hot rolling mills are used for mass thickness reduction at high temperatures whereas the cold rolling mills are used as secondary rolling operations to attain more precise dimensional and mechanical properties.

See more ideas about rolling mill jewelry techniques jewelry making tutorials. Hollteck has remained at the forefront of casting technology through the use of computerised CAD design and CAM manufacturing. For our optimum design we need to know your general rolling mill schedule comprehensive plan and detailed specifications as below.

The course covers metal deformation in the roll gap force torque and power requirements and temperature and microstructure evolution during rolling and controlled cooling. Hotion also would l ike to. Hollteck is now recognised as a world leader in the design and manufacturing of Rolling Mill Guides and associated Mill Equipment.

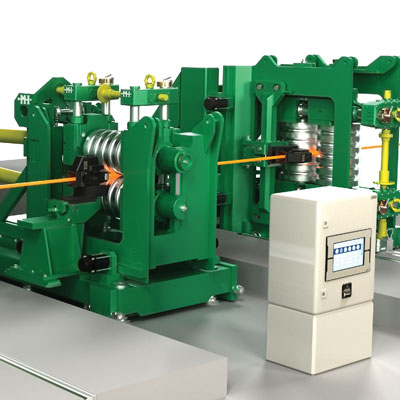

The slabs are further hot rolled into plate sheet rod bar rails and other structural shapes like angles channels etc. The exit guides of the roughing mill are to ensure optimum delivery of the stock being rolled in the mill stand as well as smooth transition through the mill stands. The roller guide boxes have simple design which ensures durability standards easy installation and smooth operation in diverse rolling conditions.

The range and quality of Hollteck guide types far exceed that of any other competitor. Billets will go through the guide plates and come into the mill rolls. Two high rolling mills.

Steel type and grade. Conversion of steel into such commercially important sections is usually done in another rolling mill called merchant mill. Most jewelers prefer a combination rolling mill because they work with different materials Flat rollers are used for reducing the thickness of sheet metal and imprinting patterns into the metal.

It contains two heavy rolls fixed one over the other. Provide rolling mill solutions including rolling passes design production line setup and workshop layout according to your requirements. Pass Design Grade and Ingredient of Raw Material.

Since introducing a revolutionary roller guide product in 1945 we have been leading the international steel industry and introducing a number of patented products for rolling mill systems. Ad Industrys Trusted Guide For Machinery Parts Supplies Services. The design of the exit guides of roughing mill usually comprise of two cast steel inserts having integral locking arrangement to secure two halves together.

In a rolling mill attached to a steel plant the starting point is a cast ingot of steel which is broken down progressively into blooms billets and slabs. Design guide plates according to the request. After the cross-section has been finalized and before the rolls can be designed the proper number of passes and rolling mill must be determined.

Tendem or Continuous mills. Wire rollers are used for rolling and reducing the diameter of a wire. At the same time other questions need to be answered such as.

Four high rolling mills. The housing less stands are normally arranged in horizontal-vertical no twist arrangement which allows no twist rolling which permits larger reduction and smoother rolling as it eliminates twisting oval into round passes as in the conventional oval to round sequence which results in less guide wear and simpler guide design. Have good wear resistance and better save cost.

We have experience from decades in design and supply of rolling mill equipment. We are catering to the requirement of Long Rolling Mills from 50000 TPY to 1 Million TPY on turnkey basis. Oct 1 2018 - Explore Navanites board Rolling Mill Patterns Designs on Pinterest.

Rolling models serve as theoretical foundation of mill design. The quality of our guide products are world famous for its. A rolling mill guide for use in rod mills merchant mills and the like comprising a guide box two opposed blocks mounted in the guide box on opposite sides of the mill pass line and having longitudinally extending channels in their adjacent faces separate metal plates bridging the respective channels and shaped to flt closely against the.

Cial roll pass design with designated guide Guiding is our business equipment to shape and longitudinally separate the incoming billet into two or more individual strands which will then be further rolled into finish-ed sizes. The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor. Secondary processes which can limit roll design options.

How to make inquiry. Although more convenient they sacrifice. We provide the best quality of mill guides at a lower price.

Ad Developed to CrushGrind Various Materials with an Optimum Result.

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Rolling Mill Guides Morgardshammar

China Roller Guide Mill Guide Rolling Guide Guide Assembling China Guide Roller Guide

Rolling Mill Guides Roller Spares Equipment And Guide Hotiongroup

Guiding Equipment Steel Rolling Mill Guiding Equipment Rolling Mill Guidebox Sli Rolling Technology

0 comments

Post a Comment